Recently I took umbrage to someone

mentioning the dryer method of rolling (as well as giving the website) on one

of my Joni Cornell Merino-Silk posts. Some

of you know that I have recently been making felt to promote The Gentle Roller

and Fulling Drum – a purpose built wet felting machine.

To date I’ve kept

my own counsel on the dryer method but in the interest of ensuring current and

future felt makers are better informed, I’ve decided that it would be

educational to make a couple of comments that felt-makers might wish to

consider before continuing (or starting) to use this method.

Sustainable making: Using the dryer is not a sustainable way of

making felt.

According to the

Consumer Energy Centre the clothes dryer is one of the most energy hungry

appliance in the house. A usual dryer

will use between 1800-5000 watts, say 3000 watts on average. If you are not using the heat cycle, but just

blowing air, let’s say 2000 watts on average.

On average the Gentle

Roller uses around 20 watts per hour of use.

Using the electric dryer, you’d be burning at least 100 times the energy

of a Gentle Roller.

Usually, a felt maker

will tend not to use the household dryer but an older version, which would be more

inefficient and use higher wattage. Several

felt makers who have used the dryer method have commented to me on the very

noticeable increase in their electricity bill when they are busy felting. And it’s not only your electricity bill that takes

a pounding. The environment is impacted

also.

If you are thinking

‘sustainability’, don’t think ‘clothes dryer’.

Safety:

The website which promotes the dryer method advises that for your safety

you should mount your dryer upside down, as the electrics are on the

bottom. This is incorrect and dangerous

advice.

Unless you have a

wiring schematic for your dryer you simply don’t know where the electrical

wires are located, and most will have electrical wiring at both top and

bottom. Here is a Whirlpool dryer with

wires in the top and bottom.

|

| Sourced from the internet |

Promoters of the

dryer method who acknowledge a potential safety issue should not compound their

error by giving misinformation that turning the machine upside down makes it

safe. It does not!

Insurance: If you believe “it will never happen to me”

then cancel your house insurance policy and save your money. But if you wisely have house insurance, you

want to make sure you don’t compromise it.

Your felt making bundle

probably carries more water than the damp clothes coming from the washer (irrespective

of rolling in a dry towel and securing with ties). If your dryer has a short-circuit, injuring

someone or starting a fire, you’ve provided your house insurance or public

liability insurance company (if in a rented studio setting) with an immediate excuse to

reject your claim outright.

Using an electrical

appliance to do something it was not designed to do is a misuse of an

electrical appliance and will immediately cancel most insurance policies. (Of course, you can always lie and gamble on

the consequences…)

When I first came

across the ‘dryer method’ our instructor was unable to demonstrate it because

of public liability issues – the venue managers strictly forbade using the

dryer for anything other than its intended use, as they knew their insurance

would be in jeopardy.

When I started out felting

I was chuffed that I could adapt certain materials, such as a bamboo blind or a

piece of dowel – but now that I’m mature in my practice (not to mention my body)

it’s time to be more mature and responsible regarding the equipment that I use.

Using the dryer to

roll your felt and then the washing machine for ‘finishing’ is rather like

using an iron to char your steak.

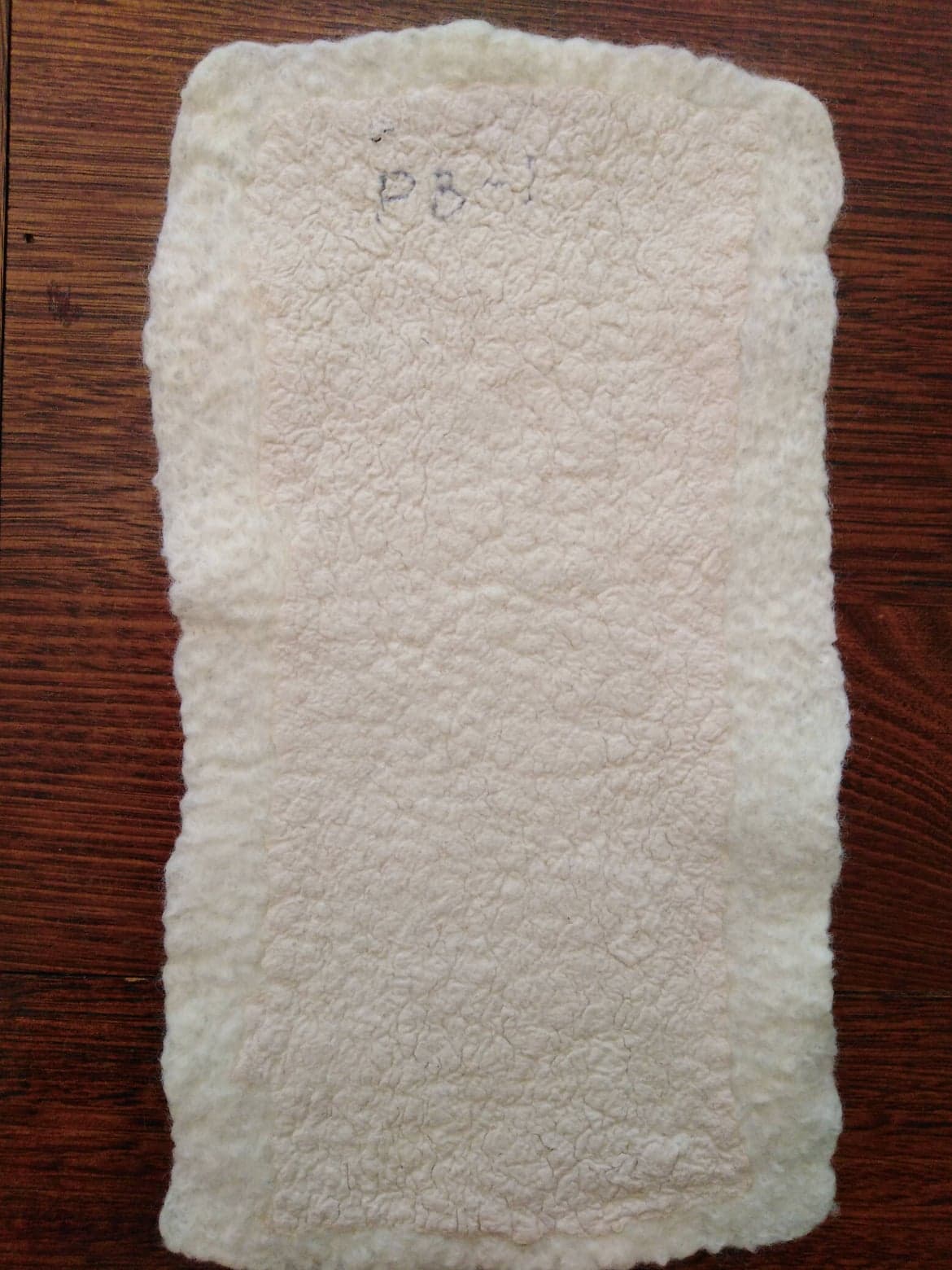

The Gentle Roller

and its Fulling Drum have been specifically designed for felt making - to take

away the tedium and labour involved in manual rolling. The fulling drum is the pièce de résistance–

as you can use it to full your felt with as much, or as little, hand

intervention as you desire to shape your finished piece.

The Gentle Roller is

safe, attractive, controllable and, as quiet as a library. It can also roll felt from super-fine Nuno to

carpet runners twice as dense as industrial carpet.

Oh, and it is not

recommended that you use it for any purpose other than felt-making 😉.

|

| The Gentle Roller - for wet felt rolling |

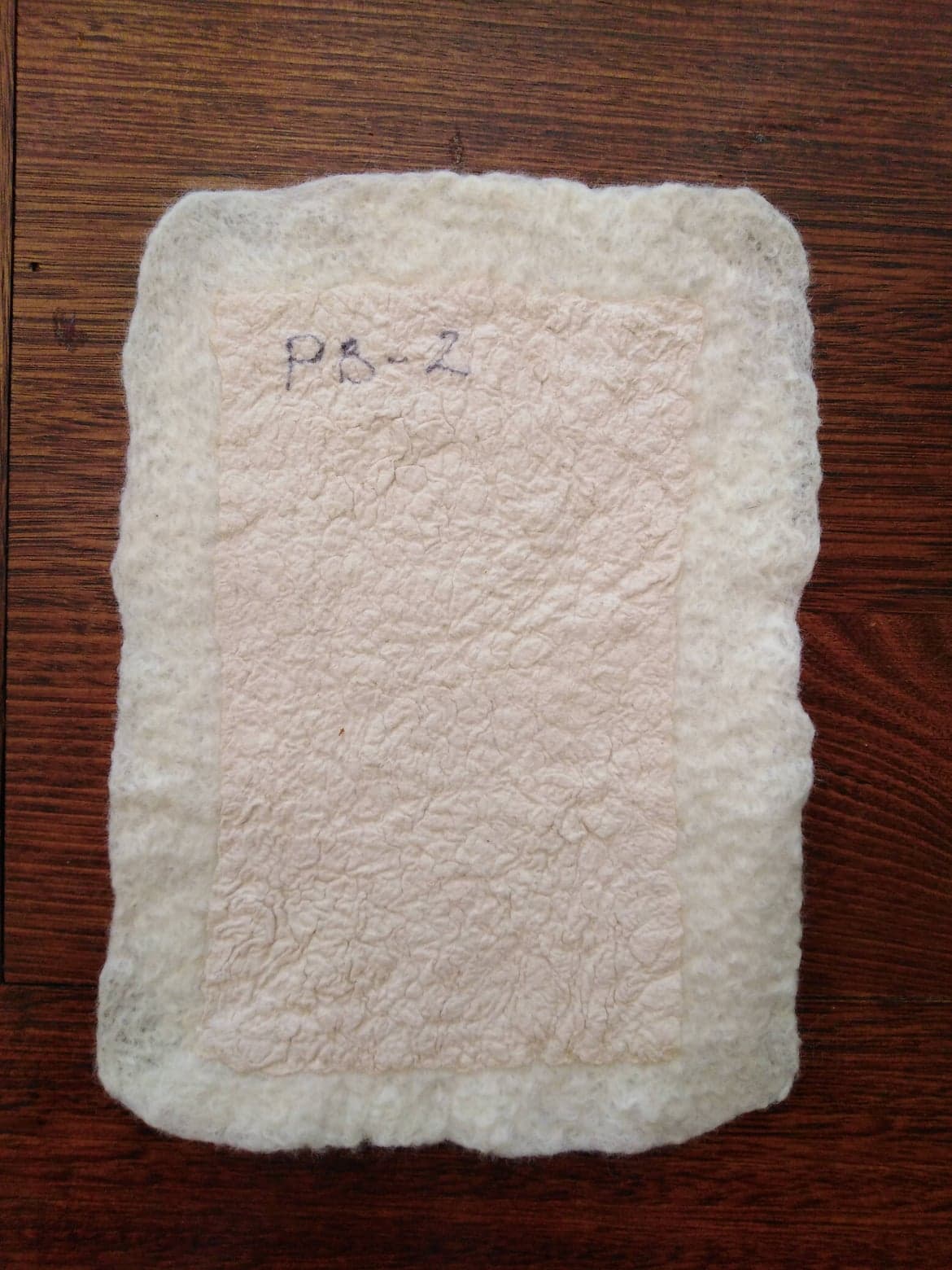

|

| The unique Fulling Drum |